Intelligent automation of manual operations, recognition of operations in production and intelligent methods in industrial safety

Intelligent online control of operations in manufacturing - the future of industrial production that has already arrived

Using advanced developments in computer vision, researchers at the HSE Tikhonov Moscow Institute of Electronics and Mathematics have developed an automated system for AI control of personnel actions during the production process.

Project goal

is to develop a software platform (framework) with a set of pre-trained machine vision models for solving typical tasks under different conditions.

Such a framework will be able to run on microcomputers, Internet of Things devices and even mobile devices, which will make it possible to reduce the cost of production automation.

The system analyses in real time the sequence of actions of the picking operator, whether robot or human. This allows you to:

- identify missed assembly steps;

- identify possible errors and unmotivated downtime;

- obtain objective data on the efficiency of employees' work in the field, transmitting it to ERP/MES systems;

- provide interactive staff training;

- monitor safety compliance, including the availability of personal protective equipment and the absence of unauthorised persons and objects in the work area;

- inform the assembly operator of a missed step or point out an error.

The automated system, unlike a live human, does not get tired, continuously monitors, objectively and unbiasedly assesses the efficiency (including indicators of labour productivity, presence of violations, etc.) of production processes. As a result, the probability of producing defective goods is significantly reduced, and the productivity and transparency of production processes increases.

The benefits of automation with artificial intelligence technology:

Cost optimisation

Automation of manual processes reduce the cost of manual labour and the use of large quantities of materials.

Quality improvement

Recognising operations in production and handling them intelligently controls the production process more accurately.

Reduced production time

Automating production and optimising manual processes reduces production time.

Improved safety

Artificial intelligence technologies optimise working conditions.

The solution is protected by the patent for invention No. 2823907 "Computer-implementable method of automatic control of assembly production".

Automatic sample construction for training

Usually, training such a complex AI system requires collecting a large amount of raw data, which is often accompanied by high production costs. However, this stage of work can be significantly optimised thanks to an innovative approach developed at the National Research University Higher School of Economics MIEM and the software for automated data collection that implements it. The details are described by the project team in the paper "Method of Automatic Images Datasets Sampling for the Manual Operations Control Systems", presented in 2023 at a major conference under the auspices of IEEE.

Usage scenarios

The current version of the stand implements the following list of automatically detected events (automated functions) to be checked by the system:

Automating the control of manual operations - the future of industrial production

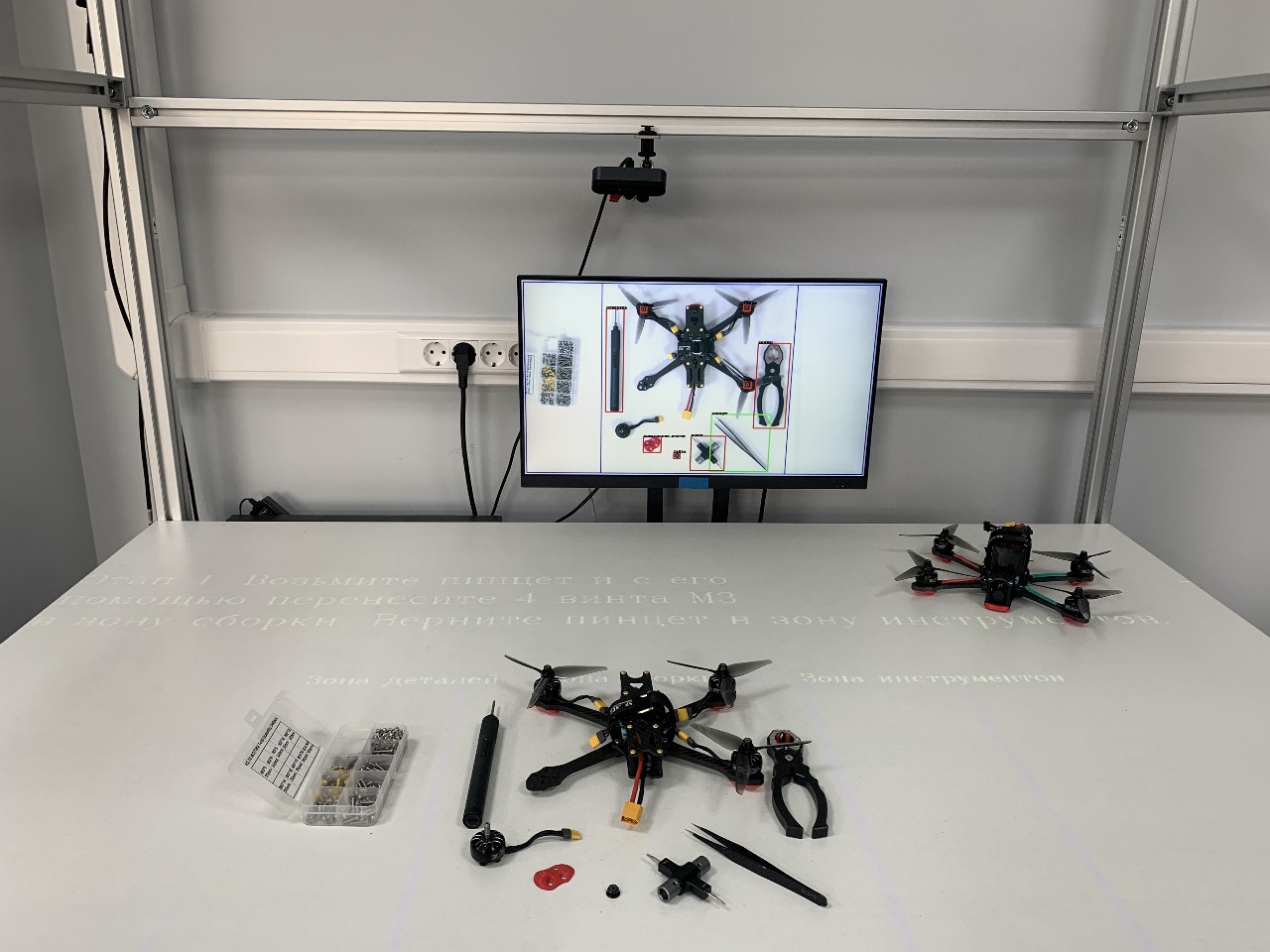

Demonstration of the operation of the Manual Operation Control System in industrial production

Materials and articles

- Sergeev A. et al. “Method of Automatic Images Datasets Sampling for the Manual Operations Control Systems”. In: 2023 XVIII International Symposium Problems of Redundancy in Information and Control Systems (REDUNDANCY). Moscow, Russian Federation, 2023, с. 194—199. DOI: 10.1109/ Redundancy59964.2023.10330200.

- “Annual interuniversity scientific and technical conference of students, postgraduates and young specialists named after E.V.Armensky - topic of the report “Development of scenarios for the application of manual operations control in industrial production"”, HSE University, 2023.

- Sergeev A., Minchenkov V., Soldatov А. Determination of efficiency indicators of the stand for intelligent control of manual operations in industrial production / Cornell University. Series Computer Science "arxiv.org". 2024. No. 2401.10777. doi

Project team